Views: 0 Author: Site Editor Publish Time: 2025-09-24 Origin: Site

You can see many main types of belt conveyor systems used today in moving materials. These include flat belt conveyors, modular belt conveyors, cleated belt conveyors, curved belt conveyors, incline or decline belt conveyors, trough belt conveyors, and sidewall belt conveyors.

Knowing the types of belt conveyor systems helps you pick the best one for your job. The table below shows key things to think about when you choose a belt conveyor:

Factor | Description |

|---|---|

Material to be Handled | Pick based on what you need to move. |

Load Weight and Size | Make sure the conveyor fits your load. |

Operating Environment | Choose a system that works in your workplace. |

Incline or Decline Needs | Use special belts for moving things up or down. |

Belt conveyor systems have different types. These include flat, modular, and cleated belts. Each type is made for a special job.

Picking the right conveyor system depends on a few things. You need to think about what material you will move. You also need to know the size of the load. The place where you use the conveyor matters too.

Belt conveyors help make work faster in many industries. They are used in manufacturing, food processing, and mining. They move materials by themselves.

Safety features are very important when you pick a conveyor system. Easy maintenance is also needed. These things help the system work well and keep workers safe.

Talking to experts can help you choose the best conveyor. They can help you find what fits your needs and business goals.

A belt conveyor is a machine that helps move things. It uses a strong belt that forms a loop between two pulleys. One pulley has a motor that makes the belt go around. This machine lets you move items fast and safely over different distances. Belt conveyor systems are very important in many industries. They help move things without much work from people. This makes jobs easier and saves time.

The market for belt conveyor systems is getting bigger. Experts think it will be worth USD 4.3 billion in 2025. By 2035, it could reach USD 6.4 billion. The market is growing by 4.0% every year.

All belt conveyor systems have several main parts. These parts work together to keep the system working well.

Component | Description | Contribution to Efficiency |

|---|---|---|

Belt | Carries items and comes in types like rubber or PVC. | Needed for moving things and lasting longer. |

Pulley | Helps guide the belt and stops it from wearing out. | Makes sure the system works smoothly. |

Drive Unit | Gives power to the conveyor, often with a motor. | Needed for steady work and moving materials. |

Idlers and Rollers | Hold up the belt and lower friction. | Help the belt move easily and last longer. |

Supporting Structure | Holds all the parts and spreads out the weight. | Keeps the system steady and safe. |

Accessories | Includes scrapers and tensioners to keep the belt straight and clean. | Stops spills and helps the system work better. |

Each part is important for how well the system works. The belt needs to be strong to carry heavy things. Rollers help the belt move without bending.

Belt conveyor systems are used in many places and for many jobs. Here are some common ways they are used:

Used in car and electronics factories for assembly lines.

Move boxes and packages in warehouses.

Carry food in processing and packaging plants.

Move coal, ore, and other things in mining.

Carry crops and grains in farming.

Sort recyclables in recycling centers.

Move luggage in airports.

Move pallets in factories.

Safely carry chemicals and medicines.

Move goods in stores and distribution centers.

Belt conveyor systems help you work faster and safer. They also help save money on workers. You can pick different types of conveyor belts for your needs. These systems make moving things easier and help your business run well.

There are many types of conveyor belt systems. Each type is made for a special job. They help move materials in different ways.

Overland belt conveyors move things over long distances. They work even on rough ground. These systems are built in parts, so they are easy to put together. They last a long time and use less energy. They also have safety features to keep workers safe. The belt moves smoothly and keeps things from spilling.

Design Feature | Description |

|---|---|

Modular Construction | Easy to build and change the layout. |

High Durability | Made for tough jobs and hard places. |

Energy Efficient Operation | Uses less power with new technology. |

Advanced Safety Systems | Has safety stops and keeps the belt in place. |

Smooth Material Handling | Stops spills and keeps things moving well. |

You can find these conveyors in mines, power plants, ports, and big factories.

Underground belt conveyors are used below the ground. They are common in mining, building, and farming. These systems help move things safely under the earth. Safety is very important here. You must stop fires and fix machine problems fast. There are rules that say you need fire-safe belts for underground work.

Tubular belt conveyors are good for moving lots of loose stuff. They use a closed tube, so dust and dirt stay inside. You can move things up steep hills and around sharp turns. This type is easy to use and does not take up much space.

Advantage | Description |

|---|---|

User-friendly | Simple to use, like other conveyor belts. |

Environmental protection | Stops leaks and keeps things safe from rain or wind. |

Flexible layout | Can turn tight corners and needs fewer transfer spots. |

High inclination | Moves things up steep slopes, up to 30°. |

Two-way transport | Can move things both ways. |

Space-efficient | Needs less room, which saves money. |

Long distance belt conveyors move things very far. Some can go almost 100 kilometers, like at Bu Craa mine. You see these in food, wood, mining, car, and recycling places. They help move lots of things quickly and easily.

Tunnel belt conveyors are good for small spaces. They use a closed pouch belt. They can go up steep hills, up to 35°. They can turn sharp corners and make less dust and noise.

Feature | Description |

|---|---|

Closed pouch belt | Only opens where you load or unload. |

Tight curve navigation | Can turn very sharp corners, as small as 0.6 meters. |

Steep incline handling | Works on steep hills up to 35°. |

Reduced transition points | Makes less dust and noise. |

Turn-key solution | Comes with design, delivery, and setup. |

Corrugated sidewall belt conveyors move things up steep or straight up. The sides keep things from falling off, even at 90°. They can carry more, spill less, and use less energy.

Sidewall conveyor belts are helpful. They work on steep hills, save floor space, and keep loose things from falling off.

Mobile belt conveyors are great for building and farming. You can move dirt, rocks, or crops easily. These conveyors help you work faster and safer, especially when tearing down buildings or moving earth.

Crawler belt conveyors can move around in mines. You can move them as the work area changes. They work well on bumpy ground and help you pile things better. You can add or take away parts to fit your job.

There are many conveyor belt systems to choose from. Each one helps with a different problem. Some, like trough belt conveyor, roller bed conveyor belts, and flexible conveyor belts, are also important in factories. Picking the right system makes moving things safer and easier.

Belt conveyor systems are used in many factories. They help move parts and products on assembly lines. These systems can do jobs automatically. This means workers do not have to lift heavy things. It makes the workplace safer and saves money. Conveyor belt systems keep things moving at the same speed. This stops slowdowns and helps make more products faster.

Benefits of belt conveyor systems in manufacturing:

You save time by moving materials automatically.

You lower mistakes and keep workers safe.

Workers can do more important jobs.

You get more work done and use less effort.

In food factories, you need clean conveyor systems. These belts use food-safe materials like stainless steel. You can wash them easily to stop germs. Modular belt conveyors move foods like bread, meat, and fruits. Spiral conveyors and bucket elevators help move food up and down. You must clean often and train workers to keep food safe.

Key features for food processing conveyors:

Use stainless steel or materials that do not rust.

Make cleaning easy with simple designs.

Add Clean-In-Place (CIP) systems for washing.

Use different conveyors for each kind of food.

Conveyor belt systems help automate warehouses. Standard belt conveyors move boxes and packages fast. Troughed belt conveyors keep loose things from falling off. Slider bed and roller bed conveyors move items smoothly. Smart conveyor systems track items as they move. You can find problems and fix them using warehouse data.

Type of Conveyor | Description |

|---|---|

Standard Belt Conveyors | Good for moving boxes and big items. |

Troughed Belt Conveyors | Raised sides keep loose things inside. |

Slider Bed & Roller Bed | Flat pans or rollers help move things smoothly. |

Belt conveyor systems are used in mines to move coal and ore. These conveyors work all the time and help save money. Multi-ply mining belts take hits underground. Straight-warp belts are strong for tunnels and rocks. Steel-cord belts are tough for hard jobs. Conveyors use less energy than trucks, so they help the environment.

Role of Conveyor Belts in Mining | Description |

|---|---|

Efficiency | Materials move without stopping. |

Cost-Effective | Saves money over time. |

Energy Efficiency | Uses less energy than trucks. |

Conveyor belt systems are used in recycling and waste centers. They move lots of trash quickly. Workers sort paper, plastic, glass, and metal from other waste. E-waste and building trash are sorted by machines. Conveyor systems keep workers safe by limiting contact with dangerous trash. Sorting is better and costs less.

Common municipal uses for conveyor systems:

Sorting recyclables from regular trash.

Automating recycling of electronics.

Moving building waste.

Handling food waste for compost.

Tip: Pick the right conveyor belt for your job. This helps you work better and keeps everyone safe.

When picking a conveyor, you need to think about a few things. The system should fit your space and move your materials well. It should also help you reach your business goals. The table below lists what you should check before choosing:

Factor | Description |

|---|---|

The application | Decide if you need the conveyor for feeding or moving things. |

Cost | Spend money on a system that works well and lasts long. |

Available footprint | Make sure the conveyor fits in your space and is easy to fix. |

Special environments | Think about safety if your area is flammable, hot, or has chemicals. |

The products | Look at the size, weight, and how delicate your items are. |

Business goals | Choose a system that helps you work faster and grow. |

You also need to check how much weight the conveyor can hold. The type of material you move is important too. Strong steel frames and thick rollers help with heavy loads. Motors must be strong enough for your needs. If you work in tough places, pick a conveyor that can handle hard jobs.

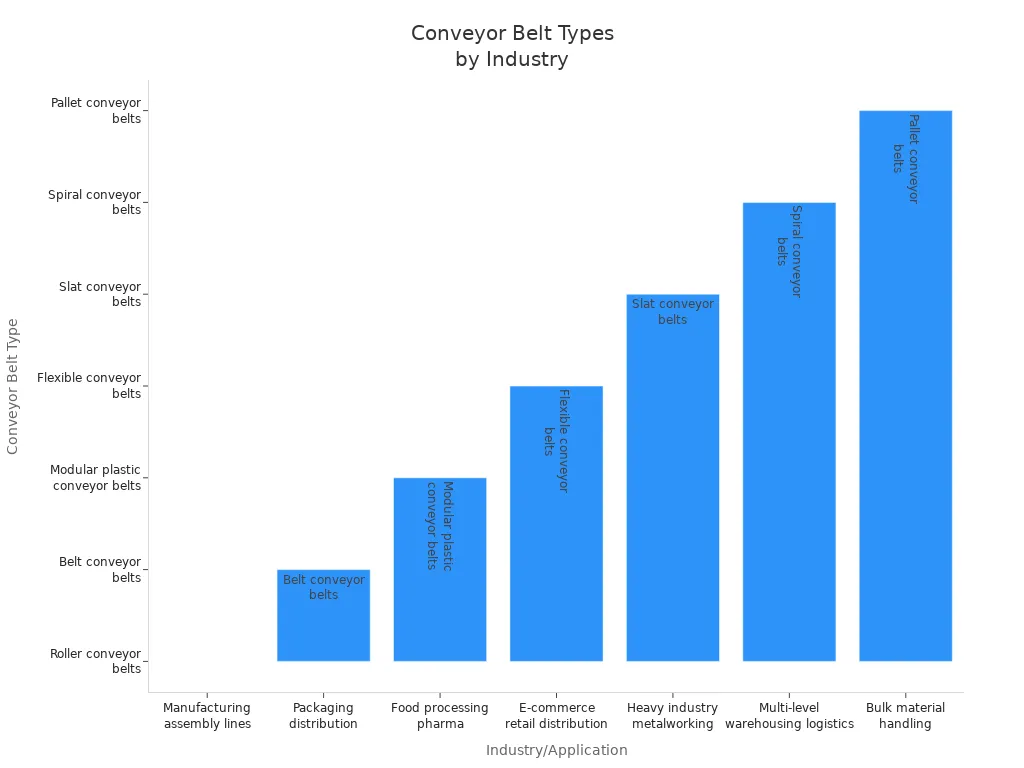

You need to pick the right conveyor for your job. Different jobs use different conveyor types. The chart below shows which conveyor fits each job:

Industry/Application | Conveyor Belt Type | Key Criteria for Selection |

|---|---|---|

Manufacturing and assembly lines | Roller conveyor belts | Good for heavy loads and fast moving. |

Packaging and distribution | Belt conveyor belts | Works for many things and handles boxes gently. |

Food processing and pharmaceutical industries | Modular plastic conveyor belts | Easy to clean and keeps things safe. |

E-commerce and retail distribution | Flexible conveyor belts | Can change shape and loads and unloads fast. |

Heavy industry and metalworking | Slat conveyor belts | Strong and can take heat from heavy or hot items. |

Multi-level warehousing and logistics | Spiral conveyor belts | Saves space by moving things up and down. |

Bulk material handling | Pallet conveyor belts | Made for heavy loads and big items. |

If you work with medicine, you need clean and washable conveyors. These keep your work area safe and clean. For warehouses, flexible and modular conveyors help move packages fast.

Here are some tips to help you choose the best conveyor:

Pick low-profile designs to fit with other machines.

Use cleated belts for moving things up or down.

Choose heavy-duty types for hard jobs.

Pick the right belt, like modular or flexible chain, for your work.

Use clean and washable conveyors for food or medicine.

Make sure your conveyor is easy to check and change.

In tough places, use strong frames and powerful motors.

Always test your items with the conveyor before you buy it. Measure your space and check how much you need to move. Talk to experts like us at Konweyour. We help many industries with modular and clean conveyors. Our team will help you find the best system to move your items safely and quickly.

You can pick from many conveyor types for different jobs. The table shows which conveyor works best for each job:

Conveyor Type | Key Applications |

|---|---|

Roller Bed Belt Conveyor | Used for airport bags, sorting mail, hand sorting, assembly, and checking products. |

Flat Belt Conveyor | Used in food making, packaging, car assembly, and places that need washing. |

Modular Belt Conveyor | Used for food, drinks, medicine, and special layouts. |

Cleated Belt Conveyor | Good for moving loose things, small grains, and items that might slide on slopes. |

If you know how conveyor systems are different, you can pick the best one. Each type has its own features and is better for some jobs.

If you are not sure, ask an expert for help. They can help you find the right conveyor and keep your work going well.

A sidewall belt conveyor has a belt with tall edges. These edges stop things from falling off. You can use it to move lots of stuff. It works well when you need things to stay on the belt.

You can use a sidewall belt conveyor in mining, farming, and recycling. It is good for moving things up or down steep slopes. This conveyor saves space and keeps your area neat.

A sidewall belt conveyor moves things up steep hills without spills. The tall sides and cleats keep items in place. You can move things straight up or at sharp angles. Flat belts cannot do this job.

A sidewall belt conveyor gives you more choices. It moves lots of things, saves floor space, and stops spills. You can move items at many angles. This helps you build a better system.