Views: 0 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

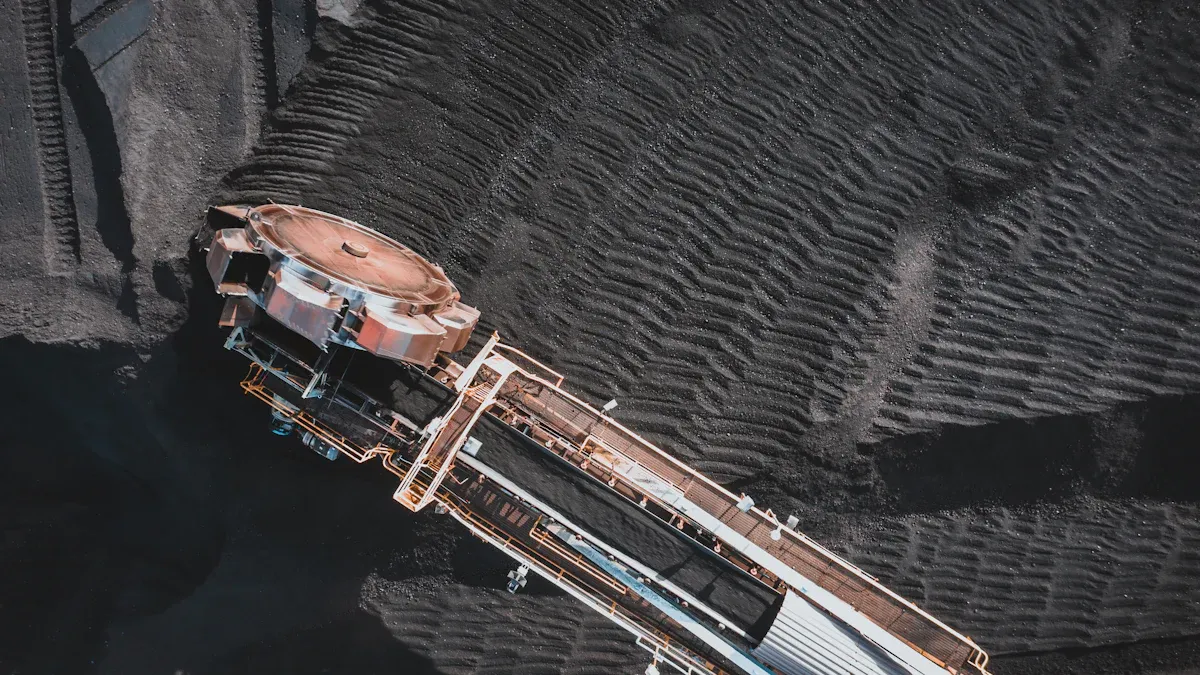

A conveyor system in mining moves things like ore, coal, and minerals. It takes them from one spot to another. You use these machines to move lots of materials safely. They also help move things quickly over long distances. Today’s conveyor designs can carry heavy loads. They work well in tough places. They also follow strict safety rules. Many mining companies pick conveyors for many reasons. They make work safer. They help work go faster. They also help with environmental goals.

Benefit | Description |

|---|---|

Increased Safety | Lowers the chance of workers getting hurt |

Eco-friendly Solution | Helps save energy and protect the environment |

High Capacity | Moves a lot of material fast |

Conveyor systems make work safer. They keep workers out of dangerous places. This lowers the chance of accidents.

These systems help work get done faster. They move materials all the time and very quickly. This saves both time and money.

Picking the right materials and designs for conveyor belts is important. It makes them last longer and need less fixing.

Checking conveyor systems often is important. Doing regular care helps them work well and stay safe.

Knowing the problems in surface and underground mining is important. It helps people pick the best conveyor systems.

A conveyor system in mining helps move lots of materials. It moves things like ore, coal, or minerals from one place to another. These systems make moving materials safer and faster. Some conveyor belts are very long and can carry thousands of tons each hour. For example, some belts in mining are over 12 kilometers long. They can move up to 2,000 tonnes every hour. They also go faster than 4 meters per second. You can find these systems in both surface and underground mines. They help meet the big needs of modern mining.

Tip: Conveyor systems help you use fewer trucks and less manual work. This makes mining safer and more efficient.

It is important to know the main parts of mining conveyor systems. Each part works together to keep everything running well and safe. Here is a table that lists the main parts and what they do:

Component | Function |

|---|---|

Belts and Chains | Move materials along the conveyor system. |

Rollers and Pulleys | Guide the belt or chain and keep it on track. |

Motors and Drives | Give power to move the belt or chain, often with electric motors. |

Controls and Sensors | Control how the conveyor works, like speed and direction. |

Support Structures | Hold up the conveyor and support its weight and the materials. |

There are many types of conveyor belts in mining. Each type is good for a different job or place. Here are some common types you might see:

Channel conveyor equipment moves materials fast over short distances.

Dribble conveyor equipment uses trays for easy sorting and packing.

Dog leg conveyor equipment has legs you can adjust for quick setup.

Stacking conveyor equipment can carry many loads and helps stack materials.

Stackable transfer conveyor equipment is easy to move and helps you work faster.

You can also find other types of conveyors in mining, such as:

Gravity roller conveyors for simple and steady moving.

Flat belt conveyors for lighter or medium loads.

Modular conveyors for special layouts and corners.

Cleated belt conveyors for better grip on slopes.

Incline or decline belt conveyors for moving things up or down.

Surface and underground conveyor systems are not the same. Surface conveyors have fewer dangers and better lights. Underground conveyor systems must handle tough places, like high heat and bad lighting. They also need to follow strict fire safety rules and use flame-resistant materials. Underground conveyors often move materials up steep slopes, which is harder on the system.

Note: Underground conveyor belts in mining have extra problems, like high heat and tight spaces. You need special materials and designs to keep them safe and working well.

Conveyor systems are very important in mining. They help move materials quickly, safely, and well, no matter where you use them.

Using a conveyor can make mining work faster. These systems move things like ore and coal quickly. You do not need as many trucks or workers. This helps you save both time and money. Conveyors keep materials moving all the time. This steady movement stops delays and keeps production high.

Conveyor systems can save about 15-35% in costs. This is compared to using trucks. You spend less on energy, fixing, and paying workers.

You need about half as many workers for a conveyor system. This means you pay less for labor.

Conveyors use less energy and cost less to fix for each ton moved.

A conveyor also makes work safer. Fewer workers need to go into dangerous areas. Automation and real-time checks help you find problems early. This lowers the chance of accidents and stops work from slowing down. You can keep your mine running safely and smoothly.

Tip: A conveyor keeps materials moving all the time. This cuts down on stops and helps you reach your goals faster.

Mining often happens in hard places. You might have to deal with very hot or cold weather. Sometimes, you work with rough or sharp materials. A conveyor can handle these problems. It uses strong parts and special features.

Feature | Description |

|---|---|

Fireproof materials | Keep your system safe in hot or fire-prone places. |

Non-corrosive materials | Stop rust and damage in wet or tough spots. |

Impact and wear resistance | Make your conveyor last longer, even with heavy or sharp loads. |

Strong construction and special belt designs help your conveyor need less fixing. Some belts use custom materials that fight damage from heat or rough stuff. These features help your conveyor keep working, even in the hardest mining sites.

Note: If you pick the right conveyor, you can trust it to work anywhere. This means less stopping and more steady moving of materials.

You face serious fire risks when you use a conveyor in mining. Fires can start quickly and spread fast. Many belts use flammable materials. This makes them easy to ignite. Fire is the main cause of property loss in these systems. If you use enclosed conveyors, heat and smoke can build up. This makes it hard to put out fires. Poor housekeeping, like letting debris pile up, gives fire more fuel. Hot work, such as welding, often starts fires near conveyors.

For a fire to start, you need oxygen, heat, and fuel. The belt itself can act as fuel, which raises the risk.

Common fire hazards in mining conveyor systems include:

Belts made from flammable materials

Enclosed spaces that trap heat and smoke

Debris and dust from poor cleaning

Sparks from hot work activities

You also need to watch out for the materials you move. Coal, petroleum coke, and cellulose catch fire easily. Dust from these materials can explode if a spark sets it off, especially in tight spaces. Cleaning and dust control help lower these risks.

Keeping your conveyor in good shape is key to safe and steady work. If you skip maintenance, you risk breakdowns and accidents. Problems like belt mistracking, slippage from wet loads, and dust buildup can stop your conveyor. Overheating in drive parts, especially in closed areas, can also cause trouble.

Belt mistracking can make the belt slip off or wear out.

Slippage happens when loads are too heavy or wet.

Dust and leftover material can build up and cause jams.

Drive parts can get too hot if air cannot flow.

Poor maintenance leads to more than just lost time. You might face big repair bills. You also put workers at risk. Accidents can happen during both operation and repair. You need regular checks and cleaning to keep your conveyor safe and reliable.

Mining sites often have rough ground and harsh weather. These factors can damage your conveyor and slow down your work. Extreme heat can weaken belts and other parts. Cold weather can make materials brittle and easy to crack. Humidity and moisture can cause belts to swell or shrink. This can lead to damage and rust on metal parts.

Weather conditions like heat and cold cause wear and tear.

Humidity and moisture can damage belts and rust metal.

Sunlight can break down rubber and make it brittle.

Chemicals, such as acids, can eat away at parts.

You need to check your conveyor often if you work in tough climates. Using the right materials and regular upkeep helps your conveyor last longer and work better.

Tip: Good housekeeping, regular checks, and using strong materials help you avoid many risks in mining conveyor systems.

You should pick the right materials and belt designs. This helps your conveyor stay strong. In mining, belts carry heavy and sharp loads every day. The right belt can stop early damage and save money on repairs. Here are some best ways to do this:

Choose belts that can handle heavy and sharp things.

Use belts with extra strength so they last longer.

Make sure belts can hold heavy loads without sagging.

Pick belts that resist wearing out from rough use.

New belt designs help your conveyor last longer too. Some pulleys use ceramic lagging and thick wing bars. These parts help stop wear and make the system work better. The Vortex® design is good for tough and rough areas. These upgrades help your conveyor work well, even in hard mining places.

Tip: Strong materials and smart designs help your conveyor keep working and need fewer repairs.

You need to keep workers safe near conveyors. Good safety systems and rules help stop accidents. Here is a table with some of the best safety features:

Safety Feature | Description |

|---|---|

Proper Guarding | Stops people from touching moving parts and dangerous spots. |

Emergency Shut-Off Buttons | Lets you stop the conveyor fast if there is an emergency. |

Start-Up Warning Systems | Warns workers before the conveyor starts moving. |

Scheduled Maintenance | Regular checks find problems before they get worse. |

Personal Protective Equipment (PPE) | Keeps workers safe from many dangers. |

Lockout/Tagout (LOTO) | Stops machines from starting during repairs. |

Wireless Emergency Stops | Lets you shut down the conveyor from far away in emergencies. |

You should also follow important safety rules:

Use safety tools like emergency stops and sensors.

Make sure workers wear PPE like gloves and safety glasses.

Teach everyone how to use the conveyor safely and what to do in emergencies.

Watch workers to make sure they follow safety rules.

Follow MSHA and OSHA rules for guarding and safety.

Note: Mark pinch points and check layouts often to find new dangers.

Proactive maintenance helps your conveyor keep running and stops long breaks. You can use these steps:

Make a plan for regular checks and fixing.

Use special tools, like IoT sensors, to find problems early.

Keep spare parts ready so you can fix things fast.

Check equipment often to find small problems before they get big.

Teach your team how to use and care for the conveyor the right way.

Many top companies use predictive maintenance to stop surprise breakdowns. Real-time sensors and AI help you watch belt wear and find problems before they happen. This saves money and keeps your conveyor working well.

Tip: Taking care of your conveyor early means fewer breakdowns and a safer, better mining job.

Conveyor systems are common in surface mining. They move lots of rock, ore, and overburden to processing areas. Conveyors can take heavy hits and tough loads, even in bad weather. In open-pit mines, the conveyor goes from the mine to the plant. Sometimes, it travels very far. This helps you move a lot of material fast and safely.

A conveyor in surface mining gives you many benefits:

You move more material faster, so you get more done.

The system keeps running, so you do not lose time.

Automation lets you watch the conveyor as it works, so you need fewer checks.

Energy-saving parts help you spend less money.

Custom designs let you fit the conveyor to your site.

Tip: A good conveyor can move both stone and ore. This makes it useful for many surface mining jobs.

Underground mining is hard and has special problems. You need a conveyor that fits in small tunnels and can turn sharp corners. The system must climb steep slopes and carry lots of material without spilling. Dust and noise are big issues underground, so you want a conveyor that keeps them low.

Some conveyor systems, like the Sicon, use a closed pouch belt. This type can go around tight bends and up steep hills. It also keeps dust and noise down, so the air is better for workers. You also need to think about fire and air quality. Underground conveyors often use fire-resistant belts and dust control. Regular checks help you find problems early, even in small spaces.

Underground Conveyor Challenges | How You Overcome Them |

|---|---|

Narrow tunnels | Use flexible, curved designs |

Steep inclines | Choose strong, gripping belts |

Dust and noise | Pick closed or sealed systems |

Fire hazards | Install fire-resistant belts |

You can count on a conveyor to keep your underground mine safe and working well, even when things get tough.

You help make sure mining conveyor systems are safe and work well. These systems move things all the time and save money. They also work in hard places. Checking them often and using strong parts stops big repairs. This also keeps workers safe.

Key Aspect | Description |

|---|---|

Efficiency | Moves materials all the time, not like trucks. |

Cost-Effectiveness | Cuts down on worker and fuel costs over time. |

Safety | Watching and guarding helps keep workers safe. |

Use good habits and follow safety rules to keep your mine working well.

You should inspect your conveyor system every week. Look for belt wear, loose parts, and dust buildup. Regular checks help you find problems early and keep your system safe.

You should choose belts made from rubber with steel cords or fire-resistant materials. These belts last longer and handle heavy loads. Fire-resistant belts also help protect your mine from fire risks.

Yes, you can use conveyor systems in extreme climates. Pick belts and parts made for high heat or freezing temperatures. Strong materials help your conveyor keep working in tough weather.

You should use guards, emergency stops, and warning signs. Train your team to follow safety rules. Give workers gloves, helmets, and safety glasses. Safety systems help prevent accidents.

Most belts fail because of poor maintenance or using the wrong materials. You should clean your system often and pick belts made for your mining job. Good care helps your conveyor last longer.

Need a custom conveyor solution?

Contact us today to speak with our mining conveyor experts. Let’s build a system that moves your mine forward.