Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Mining operations are complex and demanding, requiring efficient transportation systems. One key component that keeps everything running smoothly is the mining conveyor belt. These belts move materials like ore and coal across vast distances, ensuring a continuous flow of production. In this article, we will explore the various types of belts used in mining and how to select the right one for your operation.

A mining conveyor belt is a continuous loop of material used to transport materials from one location to another in mining operations. These belts play a vital role in ensuring the smooth flow of materials from the extraction site to processing areas, reducing the need for manual labor and large truck fleets. The key components of a conveyor belt system include rollers, pulleys, and the belt itself, which is typically made from durable materials such as rubber, steel, or fabric. The conveyor belt system works by using an electric motor to drive the belt, which moves along a series of rollers. These systems are designed to work in extreme conditions, whether it's in underground mines, open-pit mining operations, or processing plants.

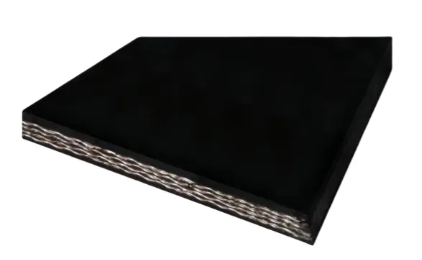

Multi-ply belts consist of several layers of fabric and rubber, creating a shock-absorbing system that handles heavy mining materials. These belts are durable, offering a longer lifespan, especially for underground mining applications where replacements are costly and difficult.

| Type of Conveyor Belt | Description |

|---|---|

| Multi-ply Conveyor Belts | Shock-absorbing layers of fabric and rubber, ideal for heavy mining materials, especially in underground operations. |

| Steel-cord Conveyor Belts | Incorporates steel cables for high tensile strength, designed for long-distance transport and high load-bearing capacities. |

| Heat-resistant Conveyor Belts | Designed to withstand high temperatures, essential for transporting materials like clinker and sintered ore. |

| Oil-resistant Conveyor Belts | Coated to resist degradation from oils, greases, and chemicals, used for oily or greasy materials. |

| Fire-resistant Conveyor Belts | Engineered to prevent the spread of fire, ensuring safety in underground and flammable mining environments. |

| Specialized Conveyor Belts | Custom belts with features like anti-static properties or enhanced abrasion resistance for specific mining needs. |

When selecting a mining conveyor belt, several critical factors need to be considered to ensure optimal performance, safety, and cost-effectiveness.

Abrasiveness: Highly abrasive materials like ore or rock require more durable belts to resist wear and tear.

Temperature: High-heat environments call for heat-resistant belts to avoid degradation under intense conditions.

Moisture Content: Materials with high moisture content may necessitate belts that resist water absorption and maintain strength.

Underground vs. Surface: Underground belts need to be more robust, especially when it comes to fire resistance and impact strength.

Weather Exposure: For surface mining, the belts need to withstand rain, extreme temperatures, and UV exposure.

Chemical Exposure: Certain mining sites may expose the conveyor belts to chemicals or oils, making it essential to use oil-resistant belts.

Belt Load and Speed: Consider the volume of material being transported and the speed at which the belt needs to move. Higher load and speed requirements will need belts with higher tensile strength and durability.

Throughput: Mining operations with high throughput demands require belts that can handle large amounts of material without compromising efficiency.

Selecting the right mining conveyor belt is a critical decision that impacts the efficiency and longevity of your mining operations. The key factors to consider when choosing the appropriate conveyor belt include material properties, the operating environment, and the specific requirements of the mining operation. It's important to choose a belt that suits the material being transported, such as choosing heat-resistant belts for high-temperature materials or oil-resistant belts for oily substances. Additionally, ensure that the belt can handle the required load and speed without compromising on performance. Understanding the specific needs of your mining operation will guide you toward the best choice for your conveyor belt system, ensuring maximum efficiency and durability.

A well-maintained mining conveyor belt is essential for optimizing operational performance and minimizing downtime. Even the highest-quality belts can experience premature wear and failure if regular maintenance is neglected. Routine checks, inspections, and adjustments are vital for extending the lifespan of the conveyor belt and keeping operations running smoothly. Performing timely maintenance ensures that the system remains in optimal condition, ultimately saving on repair costs and improving overall productivity. Failure to address maintenance issues can result in costly breakdowns and disruptions, emphasizing the importance of a proactive approach to belt care.

Routine inspections are the first line of defense against early belt failure. Regularly check for signs of wear, such as fraying, cracks, or tears, and ensure that the belt is properly aligned and tensioned. Misalignment can cause uneven wear, leading to faster deterioration and reduced belt life. Additionally, improper belt tension can lead to slippage, which may significantly impact efficiency. Simple adjustments, such as fine-tuning the tension or ensuring proper alignment, can extend the life of the mining conveyor belt significantly, reducing the frequency of costly repairs or replacements. Regular checks for any irregularities or damage help identify issues early before they escalate, improving system reliability and performance.

Another crucial aspect of conveyor belt maintenance is regular cleaning and lubrication. Over time, materials like dust, mud, or oils can accumulate on the belt, causing it to wear out more quickly. To prevent material buildup, routine cleaning using either automated systems or manual tools is necessary. Cleaning the belt reduces the friction caused by material accumulation, which can otherwise lead to premature wear and tear. Furthermore, lubrication of the rollers and other moving parts ensures smoother operation by minimizing friction and preventing parts from grinding against each other. Proper lubrication not only extends the belt's lifespan but also reduces energy consumption by promoting more efficient movement of the conveyor system. Regularly maintaining cleanliness and lubrication helps optimize the overall performance of the system.

Identifying the signs of wear early can prevent more severe damage and costly repairs. Common indicators of wear include belt slippage, excessive stretching, and uneven wear patterns. Belt slippage often occurs when the tension is incorrect or the alignment is off, leading to reduced efficiency and potential system failure. Over time, prolonged use and heavy loads can cause the belt to stretch, which impairs its overall performance and affects material handling. Uneven wear patterns, often a result of misalignment or poor material handling, are also a warning sign that the belt is not functioning optimally. By implementing a proactive maintenance schedule and addressing these signs early, mining operations can avoid downtime, reduce operational disruptions, and extend the life of the belt.

In today’s mining industry, environmental concerns are becoming increasingly important. Mining operations, especially those on a large scale, are under mounting pressure to reduce their environmental footprint. By choosing the right mining conveyor belt, companies can play a significant role in minimizing energy consumption, reducing emissions, and decreasing reliance on non-renewable materials. The mining sector has a unique opportunity to promote sustainability by selecting belts made from eco-friendly materials and using energy-efficient systems that contribute to the broader goals of sustainability. The right choices can not only benefit the environment but also improve cost-efficiency over the long term.

Modern mining conveyor systems are increasingly designed with energy efficiency in mind. Electric drive systems, for example, use electric motors that consume significantly less energy compared to traditional fuel-powered vehicles. This reduction in energy consumption not only helps lower operational costs but also reduces the mining operation's carbon footprint, contributing to environmental conservation efforts. Furthermore, energy-efficient systems are essential for minimizing greenhouse gas emissions, making them a crucial component of sustainability initiatives within the mining industry. By investing in energy-efficient conveyor systems, mining operations can align with global efforts to combat climate change and promote greener practices.

In addition to energy-efficient systems, some mining conveyor belts are made from advanced materials that contribute to the overall sustainability of operations. These eco-friendly materials help reduce environmental degradation during the belt’s production and use. For example, belts made from recycled or recyclable materials help minimize waste and promote a circular economy in the mining industry. By choosing advanced materials, mining operations can ensure that their conveyor systems not only perform well but also align with their environmental goals. Sustainable materials contribute to reducing the lifecycle impact of mining operations and support the industry's long-term ecological and economic stability.

The focus on recyclability is an important step in the mining industry's efforts to reduce waste and promote sustainability. Many mining conveyor belts are now designed to be recyclable, ensuring that they can be repurposed at the end of their service life, which helps reduce waste and conserve resources. In addition, durable conveyor belts contribute to a more sustainable lifecycle by minimizing the need for frequent replacements, thus reducing material consumption over time. Investing in long-lasting, recyclable conveyor belts not only supports sustainability but also helps lower long-term operational costs. The durability and recyclability of modern mining conveyor belts play a crucial role in creating a more sustainable mining operation, benefiting both the environment and the business's bottom line.

In the mining industry, the mining conveyor belt is an indispensable component of the material transport system. Selecting the right belt for your operation is crucial to ensure efficiency, safety, and cost-effectiveness. Whether you are dealing with abrasive, hot, or oily materials, there is a specialized conveyor belt designed to meet your needs. Regular maintenance and careful selection based on environmental factors can significantly extend the lifespan of your system and prevent costly breakdowns. By making informed decisions and investing in the right mining conveyor belt, your operations can run smoothly, reduce downtime, and boost profitability.

Always prioritize a conveyor belt that matches your specific material and environmental conditions to maximize efficiency and longevity.

Konweyour offers specialized conveyor belts for the mining industry. Their products are designed to meet the specific demands of mining operations, ensuring reliable performance and longevity. Konweyour's solutions help improve safety, reduce downtime, and optimize mining operations.

A: A mining conveyor belt is a continuous loop used to transport materials like ore, coal, and minerals across mining operations. It plays a vital role in material handling and efficiency.

A: When selecting a mining conveyor belt, consider factors like material properties, environmental conditions, and load capacity. Different belts are suited for different mining environments.

A: There are several types, including multi-ply belts, steel-cord belts, and heat-resistant belts, each designed to handle specific materials and conditions in mining operations.